Portable Cement Silos: Revolutionizing Construction Efficiency

The construction industry is evolving rapidly, driven by the need for increased efficiency, enhanced safety, and cost-effectiveness. One of the most significant innovations that have emerged in recent years is the portable cement silo. These structures play a crucial role in cement storage and dispensing, streamlining operations and ensuring that construction projects run smoothly. In this comprehensive article, we will delve into the intricacies of portable cement silos, exploring their design, benefits, applications, and the cutting-edge technology from Polygon Machinery.

What is a Portable Cement Silo?

A portable cement silo is a self-contained storage unit designed specifically for holding cement and other powdered materials. Unlike traditional, stationary silos, portable cement silos can be easily transported to different job sites, providing flexibility and convenience. They are typically made from durable steel and are available in various sizes, accommodating various project requirements.

Benefits of Using Portable Cement Silos

The adoption of portable cement silos comes with a myriad of advantages that make them an essential component of modern construction projects. Below are some of the key benefits:

- Mobility: Their portability allows for easy relocation between job sites, minimizing downtime and maximizing productivity.

- Cost-Effective: Investing in a portable cement silo reduces transportation costs, as you can keep a sufficient supply of cement on-site.

- Quick Setup: These silos can be set up rapidly, providing immediate access to materials without the delay of traditional storage solutions.

- Reduced Waste: With precise dispensing systems, portable cement silos minimize wastage of materials, contributing to more sustainable practices.

- Built-in Safety Features: Many modern silos come equipped with safety features that reduce risks associated with handling and storing cement.

Applications of Portable Cement Silos

Portable cement silos find application in a wide range of projects, reflecting their versatility and efficiency. Key applications include:

1. Residential Construction

From small homes to large residential complexes, portable cement silos support various construction activities, ensuring that cement is easily available when needed.

2. Commercial Development

Commercial buildings, warehouses, and office complexes require substantial amounts of cement, which can be conveniently managed with portable silos on-site.

3. Road Construction

During road and infrastructure projects, these silos provide mobility and quick material access, enhancing operational efficiency.

4. Paving and Concrete Work

The paving industry benefits significantly from portable cement silos, which allow firms to manage the supply of premixed concrete easily.

5. Precast Concrete Manufacturing

Manufacturers of precast concrete products utilize portable silos to store cement, ensuring constant supply during production cycles.

How Portable Cement Silos Work

Understanding the operational mechanism behind portable cement silos is essential for project managers and construction professionals. Here are the fundamental components that enable these silos to function effectively:

- Storage Capacity: Portable silos come in different storage capacities, allowing for a wide range of material storage needs.

- Feeding System: A screw conveyor or gravity-fed system dispenses cement from the silo into mixers or delivery vehicles.

- Loading Mechanism: Silos can be filled quickly via pneumatic or conventional loading methods, minimizing downtime.

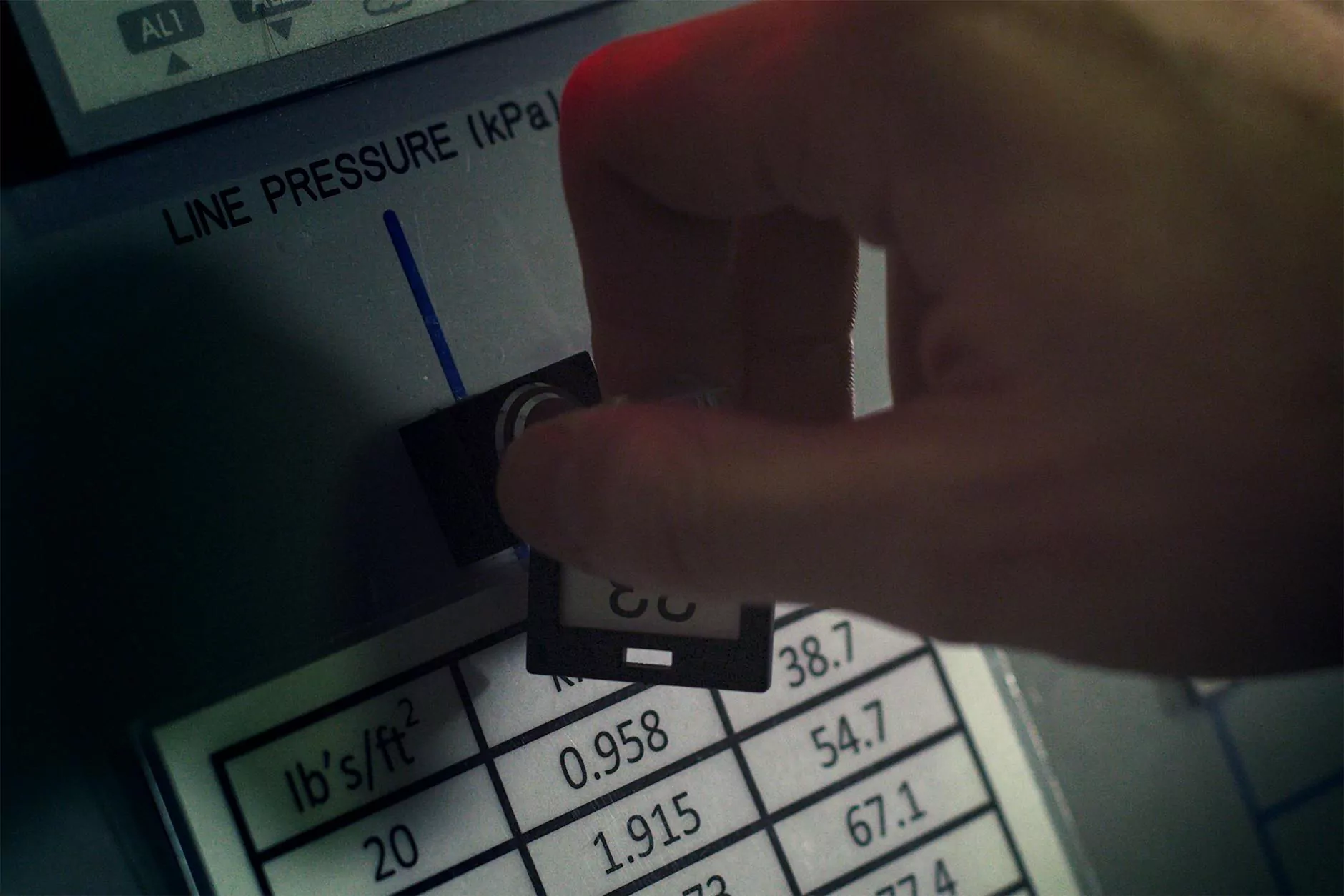

- Control Systems: Modern portable cement silos are equipped with digital control systems that monitor levels and dispense material accurately.

The Technological Edge: Innovations in Portable Cement Silos

With the rapid advancement of technology, portable cement silos have also evolved. Here are some of the innovative features and technologies that enhance their functionality:

1. Digital Monitoring Systems

Modern silos can integrate with IoT (Internet of Things) systems, allowing for real-time monitoring of cement levels and usage metrics. This data can lead to smarter inventory management and ordering processes.

2. Automated Dispensing

Automated systems ensure precise dispensing of materials, reducing the chances of human error and ensuring consistent quality in concrete mixing.

3. Environmental Controls

Improved designs include features that minimize dust emissions, promoting a safer working environment and compliance with environmental regulations.

4. Self-Contained Units

Many portable silos come equipped with their own power sources and hydraulic systems, allowing them to operate independently, regardless of the site’s existing infrastructure.

How to Choose the Right Portable Cement Silo

Selecting the right portable cement silo involves several considerations to ensure it meets your project needs efficiently. Here are some important factors to consider:

- Capacity Requirements: Assess your daily cement usage to determine the appropriate capacity of the silo.

- Transportability: Ensure that the silo is equipped with features that facilitate easy transportation and setup.

- Durability: Check the quality of materials used in the silo’s construction to ensure it can withstand harsh job site conditions.

- Maintenance Services: Choose suppliers, like Polygon Machinery, that offer excellent after-sales services and maintenance support.

- Technology Integration: Opt for silos equipped with modern technological features that enhance monitoring and usage efficiency.

The Role of Portable Cement Silos in Sustainability

The construction industry faces increasing demands for sustainability, and portable cement silos are tailored to meet this challenge effectively. Here’s how they contribute to sustainable practices:

1. Waste Reduction

By enabling precise measurements and minimizing spills, portable silos reduce waste associated with material handling.

2. Energy Efficiency

Modern cement silos are designed for energy efficiency, ensuring that they consume less energy during dispensing and mixing processes.

3. Recyclable Materials

Many portable silos are constructed from recyclable materials, helping to lower the carbon footprint of construction activities.

4. Reduced Transport Emissions

Having cement readily available on-site reduces the need for continuous transport of materials, thereby minimizing emissions associated with heavy truck movements.

Conclusion: The Future of Portable Cement Silos

As the construction landscape continues to evolve, the role of portable cement silos becomes increasingly vital. Their ability to improve efficiency, reduce costs, and support sustainability initiatives makes them indispensable for contractors and builders alike. With ongoing innovations and cutting-edge technology, companies like Polygon Machinery are at the forefront of this revolution, providing businesses with the tools they need to succeed in a competitive market.

In summary, portable cement silos offer a powerful solution for modern construction challenges, bridging the gap between traditional practices and the demands of contemporary project management. By investing in these silos, construction companies can enhance their operational capabilities and contribute to a more sustainable future.

For further information regarding portable cement silos and how they can benefit your construction operations, visit Polygon Machinery.