Unlocking Manufacturing Excellence with Rapid Prototype China

Introduction to Rapid Prototyping

Rapid prototyping is a game-changing manufacturing technology that allows businesses to design, test, and refine products quickly and efficiently. Rapid prototype China stands at the forefront of this innovative approach, offering unparalleled speed and precision. In a fast-paced market where time-to-market can dictate success or failure, leveraging state-of-the-art prototyping services is more crucial than ever.

The Importance of Prototyping in Product Development

Prototyping plays an essential role in product development, enabling companies to visualize their concepts before committing to full-scale production. A well-executed prototype can:

- Validate Ideas: Ensure that the concept meets customer needs.

- Reduce Development Costs: Identify design flaws early to avoid expensive changes later.

- Enhance Communication: Facilitate discussions between stakeholders by providing a tangible reference point.

- Accelerate Time-to-Market: Speed up the development cycle through iterative testing and feedback.

Rapid Prototype Services in China

China has emerged as a leading hub for rapid prototype services thanks to its robust manufacturing infrastructure, skilled workforce, and advanced technology. Here are some of the primary services offered:

3D Printing

One of the most popular forms of rapid prototyping, 3D printing allows for quick creation of prototypes using various materials. The technology can support diverse applications from consumer products to aerospace components, showcasing versatility and efficiency.

CNC Machining

CNC machining involves using computer-controlled machines to create parts of high precision. This method is widely used in industries that demand tight tolerances and complex geometries, making it an ideal choice for metal fabricators seeking to produce exact prototypes.

Injection Molding

Injection molding is an effective and fast way to produce a large number of identical parts. Although traditionally seen as a mass production method, it can also be adapted for rapid prototyping, particularly for plastic components.

Vacuum Casting

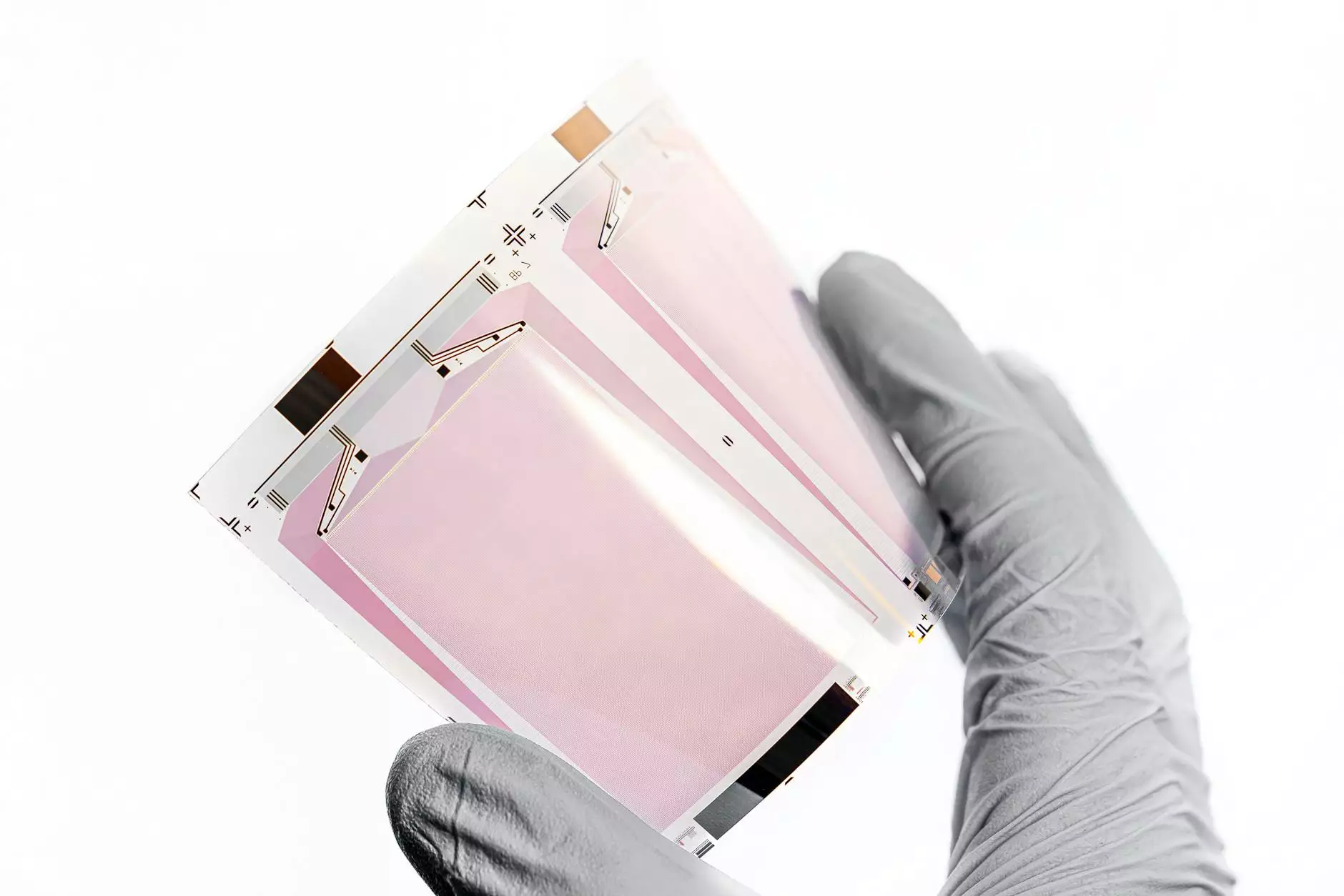

This technique is ideal for low-volume production runs, providing high-quality silicone molds that can produce parts with complex designs. Vacuum casting has the capability to replicate fine details, making it a preferred choice for industries such as automotive and consumer electronics.

Benefits of Choosing Rapid Prototype China

Selecting rapid prototype China as your manufacturing partner brings numerous advantages:

- Cost-Effectiveness: Lower labor and material costs can result in substantial savings for companies.

- Speed: Advanced technologies and streamlined processes in China lead to faster turnaround times.

- Quality: Chinese manufacturers often employ rigorous quality control processes to ensure high standards.

- Expertise: A deep pool of engineering talent allows for innovative design solutions and technical support.

Selecting the Right Partner for Rapid Prototyping

When choosing a rapid prototyping partner in China, consider the following criteria:

Experience and Expertise

Look for a company with a proven track record in the industry relevant to your product. Investigating their portfolio can provide insight into the types of projects they have handled.

Technology and Capabilities

Ensure that the manufacturer utilizes the latest technology and machinery, which can directly affect the quality and speed of your prototypes.

Communication

Effective communication is key to successful collaboration. Choose a partner that offers clear, transparent communication and can accommodate your needs.

Customer Support

A quality service provider should offer comprehensive customer support to assist you throughout the prototyping process, including after-sales support.

Latest Trends in Rapid Prototyping

Staying abreast of trends can give your company a competitive edge. Some of the recent developments in the field of rapid prototyping include:

Integration of Additive Manufacturing

Additive manufacturing technologies are becoming more integrated into conventional manufacturing processes, enhancing efficiency and flexibility.

Biomaterials and Sustainable Practices

The use of biodegradable materials and eco-friendly processes is gaining traction as businesses prioritize sustainability. Rapid prototyping is evolving to support this shift, with innovations in various materials.

Rapid Prototyping Software Innovations

Advances in design software are making it easier for manufacturers to create prototypes faster and with greater accuracy, leading to reduced lead times and improved quality outcomes.

Real-World Applications of Rapid Prototyping

Rapid prototyping is reshaping multiple industries. Here are some notable applications:

Automotive Industry

In automotive manufacturing, rapid prototyping allows for the testing of parts and systems, enhancing safety and performance while accelerating time-to-market for new models.

Aerospace Sector

Aerospace companies leverage rapid prototyping for complex components and assemblies, where precision and reliability are paramount.

Rapid prototyping is commonly used in the consumer electronics field, enabling companies to rapidly develop and refine new gadgets, improving consumer satisfaction.

Conclusion

In the highly competitive landscape of modern manufacturing, the advantages of rapid prototype China are undeniable. Leveraging advanced technologies, a skilled workforce, and a commitment to quality can help your business stay ahead of the curve. By adopting rapid prototyping practices, you can ensure innovation drives your product development process, leading to better outcomes, satisfied customers, and ultimately, greater success in the marketplace. Embrace the future of manufacturing today by harnessing the power of rapid prototyping in China.