Understanding Injection Molding Plastic Products

Injection molding plastic products represent a transformative approach in the manufacturing landscape, enabling the creation of intricate and high-quality components used across a myriad of industries. At Deepmould.net, we specialize in delivering refined solutions through our skilled metal fabrication services, laying the groundwork for superior injection molding processes.

What is Injection Molding?

Injection molding is a manufacturing process that involves injecting molten material into a mold to achieve a desired shape. This method is exceptionally popular in producing plastic products due to its efficiency and reproducibility. The process involves several key steps:

- Material Selection: The process begins with selecting the appropriate thermoplastic or thermosetting plastic that meets the product requirements.

- Pelletizing: The chosen plastic is formed into pellets that are easy to transport and melt.

- Heating: Pellets are heated until they become molten and flow easily.

- Injection: The molten plastic is injected into a mold, where it cools and solidifies into the final product's shape.

- Mold Removal: Once cooled, the mold is opened, and the finished product is ejected.

Advantages of Injection Molding Plastic Products

Utilizing injection molding plastic products offers a multitude of advantages for manufacturers, which significantly contribute to enhanced productivity and cost-efficiency:

- Cost-Effectiveness: High-volume production reduces the cost per item, making it an economical choice for mass production.

- Accuracy: Injection molding allows for exceptional precision, enabling manufacturers to produce intricately designed components without sacrificing quality.

- Versatility: This method is compatible with a wide range of materials, including various types of plastic, thereby catering to different applications.

- Reduced Waste: The process generates minimal waste, contributing to more sustainable manufacturing practices.

- Continuous Production: Automated processes enable continuous production, enhancing throughput.

Industry Applications of Injection Molding

Injection molding has a vast array of applications across different industries. Here are some notable examples:

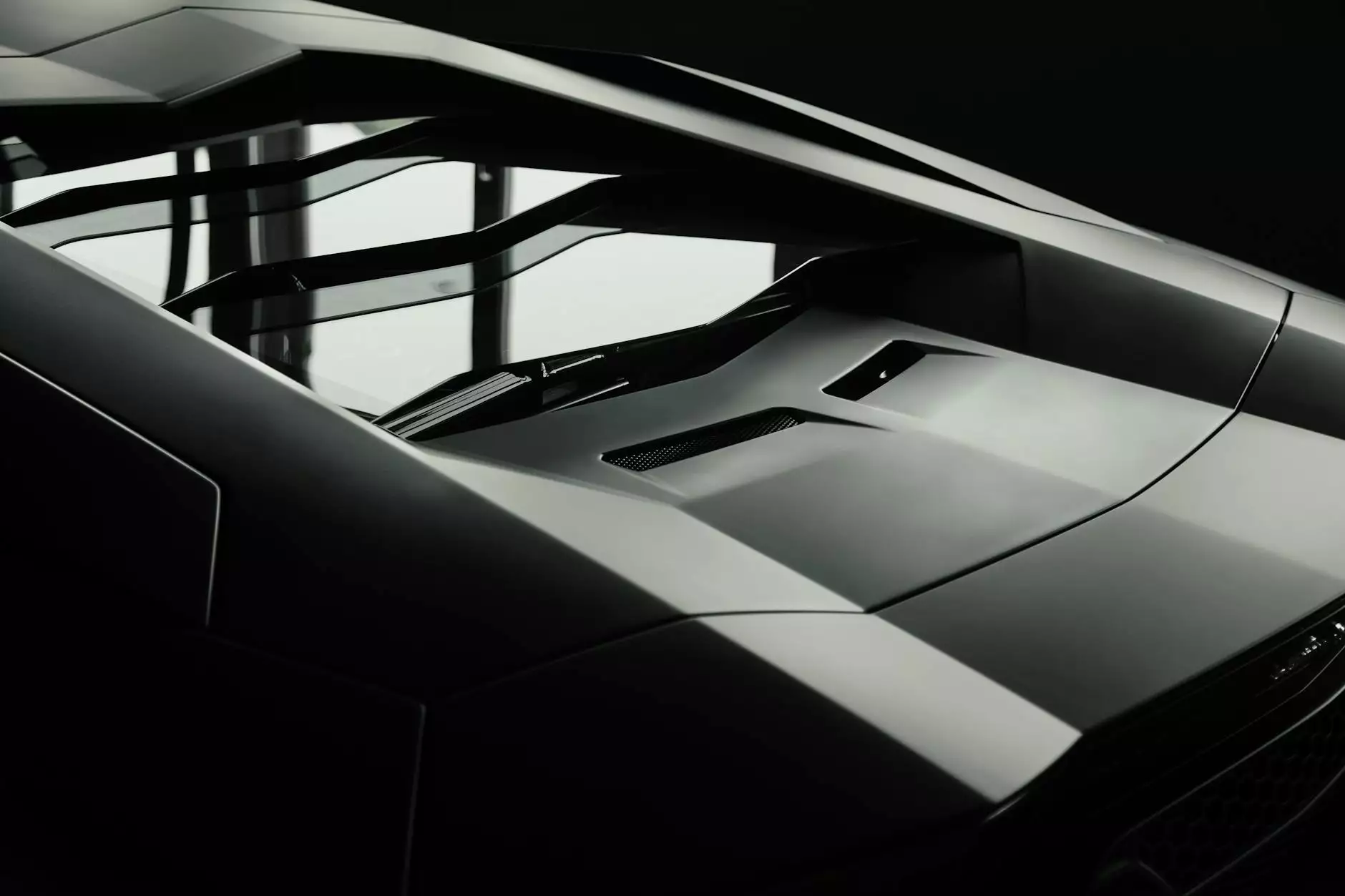

1. Automotive Industry

The automotive sector extensively utilizes injection molding plastic products to manufacture components such as dashboards, bumpers, and interior trims. The precision and customization options available through this method allow for better vehicle aesthetics and functionality.

2. Consumer Goods

Many consumer products benefit from this process, including household items, packaging containers, and toys. The ability to create complex designs makes injection molding ideal for innovative product development.

3. Medical Devices

The medical field relies heavily on injection-molded components for devices, tools, and equipment. These products must adhere to strict regulations for safety and efficacy, making injection molding a preferred choice due to its reliability and precision.

4. Electronics

Electronics casings and components are often manufactured using injection molding, providing excellent protection and durability for sensitive instruments.

Deepmould.net: A Leader in Injection Molding and Metal Fabrication

At Deepmould.net, we understand the intricacies involved in the injection molding plastic products domain. Our team of experts is dedicated to providing high-quality metal fabrication services that complement our injection molding offerings. Here’s what sets us apart:

- Expertise: Our professionals possess extensive knowledge and experience in both injection molding and metal fabrication, ensuring seamless integration of these processes.

- State-of-the-Art Technology: Utilizing the latest technology, we ensure that our services are efficient and produce top-quality results, meeting the stringent demands of our customers.

- Custom Solutions: We recognize that each project is unique. We offer tailored solutions to meet specific customer requirements, maximizing both functionality and aesthetics.

- Quality Assurance: Commitment to quality is at the forefront of our operations, ensuring that every product meets the highest industry standards.

The Future of Injection Molding Plastic Products

The landscape of manufacturing is continually evolving, with injection molding plastic products playing a pivotal role in the future of production. Several trends and innovations are shaping this industry:

- 3D Printing Integration: Combining 3D printing technology with injection molding can streamline prototyping and production processes, allowing for quicker iterations and more complex designs.

- Sustainable Materials: There is a growing demand for eco-friendly materials, and manufacturers are continuously researching biodegradable and recyclable plastics to align with sustainability goals.

- Smart Manufacturing: The integration of IoT (Internet of Things) in manufacturing processes is enhancing monitoring, control, and efficiency of injection molding operations.

- Market Expansion: With emerging markets seeking innovative solutions, the injection molding industry is poised for growth, providing opportunities for manufacturers worldwide.

Conclusion

In conclusion, injection molding plastic products remain essential in modern manufacturing, offering unparalleled advantages in terms of efficiency, cost, and versatility. As a leading provider of metal fabrication services, Deepmould.net is committed to delivering high-quality solutions that harness the potential of injection molding. By embracing innovation and sustainability, we are poised to meet the evolving demands of various industries. Whether you are in the automotive, consumer goods, medical, or electronics sector, partnering with us ensures you receive products that meet the highest standards of excellence.